BLACK MASTERBATCH – Polyethylene (PE) Based

BLACK MASTERBATCH – Polyethylene (PE) Based

Product Description

Black Masterbatch based on polyethylene (PE) carrier resin, formulated with high-quality carbon black to deliver deep black coloration, excellent UV resistance, and uniform dispersion. It is suitable for LDPE, LLDPE, and HDPE applications including film, extrusion, blow molding, and rotomolding processes.

KeyFeatures & Advantages

- High jetness and uniform color distribution

- Excellent dispersion with no agglomeration

- Enhanced UV and heat stability for outdoor applications

- Suitable for LDPE / LLDPE / HDPE grades

- Maintains mechanical strength and surface finish

- Easy to process with excellent flow properties

- Compatible with most PE-based masterbatches and additives

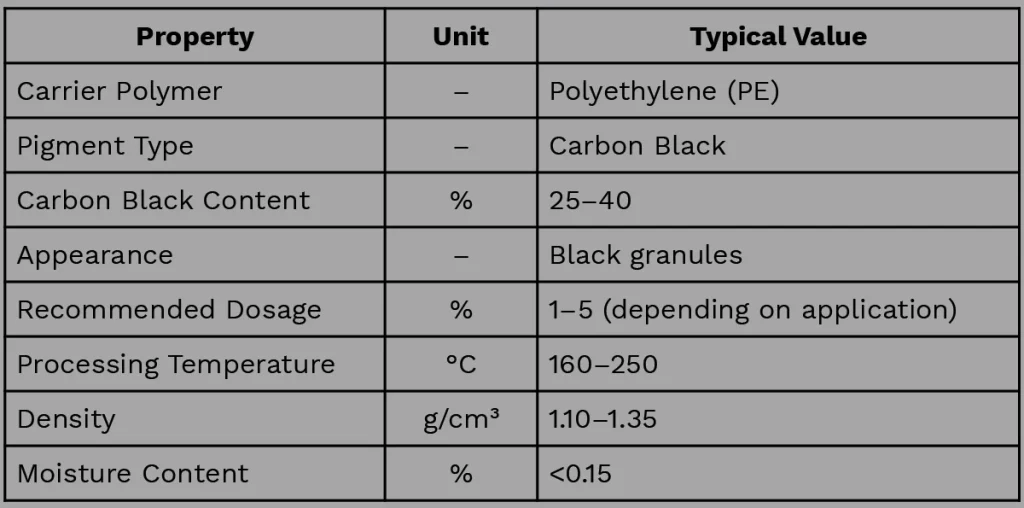

Typical Properties

Applications

- Blown film (LDPE, LLDPE, HDPE)

- Extrusion coating

- Blow molded containers and tanks

- Pipes and sheets

- Rotomolded and thermoformed products

Processing Guidelines

- Recommended let-down ratio: 1–5%, depending on the required color strength and opacity.

- Can be processed on standard extrusion, injection, and blow molding

- Ensure material is dry and moisture-free before processing.

Packaging & Storage

- Supplied in 25 kg moisture-proof PE laminated bags.

- Store in a cool, dry, and shaded environment below 40°C.

- Avoid direct sunlight and high humidity.